Feb 10, 2021 | 4 minutes

Automation for Climate Change: How OHoE Uses Make to Accelerate Industrial Transformation

Learn how Open House of Energy uses Airtable, JotForm, Stacker, and Integromat to accelerate industrial transformation in the field of energy efficiency.

Few initiatives have more impact than industrial transformation in the fight against climate change.

Although the scientific consensus is clear about the role of industrial activity in the ongoing situation, mentions of industrial transformation emerge few and far between in the greater narrative of climate emergencies.

In this case study, we will go over the story of Open House of Energy, a Munich-based company that is accelerating industrial transformation projects for multiple facilities with the help of automation.

But before we get to that, let’s address the obvious: What is industrial transformation?

Industrial transformation: A brief definition

In its simplest acceptance, industrial transformation (IX) is an approach that relies on digital technologies to produce significant, positive changes in industrial operations.

Unlike continuous improvement schemes, IX takes place within a clearly defined timeframe, during which upgrades and changes are implemented for immediate results.

As expected, IX requires almost surgical coordination of efforts, assets, and parties to roll out the necessary changes. This is also the reason why the automation of IX-related processes is vital to its success, as it reduces implementation costs and times, and also the chance of human error.

Now, let’s take a look at how Open House of Energy uses a simple tech stack to accelerate industrial transformation in the field of energy efficiency.

Mastering the art of industrial change

Climate change, energy crisis, new regulations, and more: the challenges of our time affect many industries, regardless of size, history, or sector.

But where there’s a problem, there’s also an opportunity for new business models that develop innovative approaches to produce solutions and results.

This is the case with Open House of Energy (OHoE), a service provider for industry and commerce that helps companies improve their energy efficiency. OHoE specializes in companies that have to comply with strict standards, but lack the resources to do so in a fast, efficient manner.

In order to help them overcome this problem, OHoE has developed a novel approach for their customer’s energy-related industrial transformation projects. This new approach relies heavily on automation and saving all the involved parties a great deal of resources.

Now, let’s see how it works.

Energy-saving processes, powered by automation

The cornerstone of OHoE’s industrial transformation projects is represented by extensive data covering the energy needs, consumption, and efficiency of one or more industrial facilities.

As you can sense, this data is not always available, updated, or cohesive.

In the traditional way of gathering it, internal and external specialists record the current status of industrial facilities, focusing on energy use and potential savings.

This outdated data-gathering process is time and personnel-intensive. Carrying out in-person surveys with dozens of employees, stakeholders, and external partners is particularly demanding and inefficient.

From this experience - and coupled with the requirements of industrial clients - OHoE developed the product idea of a digital solution to gather key data. The goal was to expand the on-site inventory, and also to simplify the entire process for both sides.

However, the usual management tools did not allow for the necessary depth and agility, so the choice fell on a custom solution reliant on widely available apps.

The easy way to gather data from multiple sources

Custom software is expensive, hard to develop, and costly to maintain. With this in mind, OHoE turned to Wemakefuture, a business process automation agency that creates custom solutions from well-known apps.

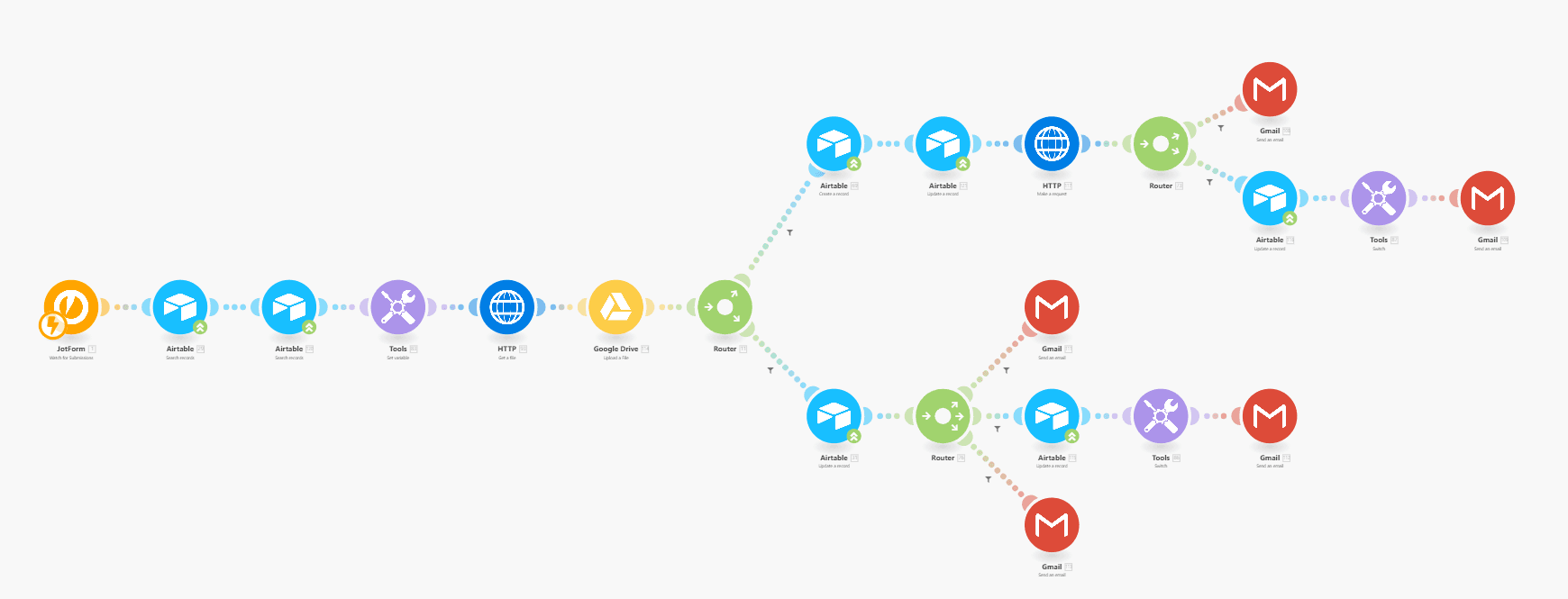

The first step was to implement a JotForm digital form that OHoE's customers could fill out independently and from any location.

This form resulted in a huge amount of data for each individual company, which was almost impossible to qualify and organize. So, in order to organize the data, Airtable was onboarded.

Airtable stands in the background as an automated database that collects all data records from the forms and assigns them correctly.

To visualize the resulting data, a customizable user interface based on Airtable was chosen: Stacker.

Stacker allows clients to access and view their own data from anywhere, guaranteeing the transparency of the process.

Jotform, Airtable, and Stacker laid the foundation for the successful automation of surveys.

The resulting survey data is then correctly assigned and qualified in Airtable, and depending on the answers, OHoE's customers receive a score, after which another, more comprehensive questionnaire is issued.

Various automated emails are also sent based on this score.

At the heart of all the automated process is Make. The automation platform is the ideal solution to connect JotForm, Airtable, and Stacker; without it, an immense quantity of manual work would still be needed to effectively streamline the data-gathering effort.

Now, what happens after the data is gathered, and qualified?

The modular structure of OHOE's automation creates a sustainable and future-proof solution that can be gradually expanded with further additions.

If customers achieve a fixed score in both the 1st and 2nd questionnaires, the individual suggestions for improving energy efficiency are provided in Stacker.

In turn, these suggestions are evaluated by the customers according to their feasibility and efficiency in order to find an ideal solution together.

Wasting time is wasting energy

By replacing a personnel-intensive consultation process with a digital, location-independent solution, OHoE’s staff, experts, and partners saved an enormous amount of time.

In addition, they solved an important customer-side problem: with more time left for identifying problems and delivering the answers, industrial transformation projects became more feasible. Once you reduce the pressure and the resources involved in delivering potential solutions, these arise.

For Open House of Energy, automation translated into quick and valuable results. In addition, the modularity and iterative nature of its automated stack enabled further developments and applications to tackle other necessities.

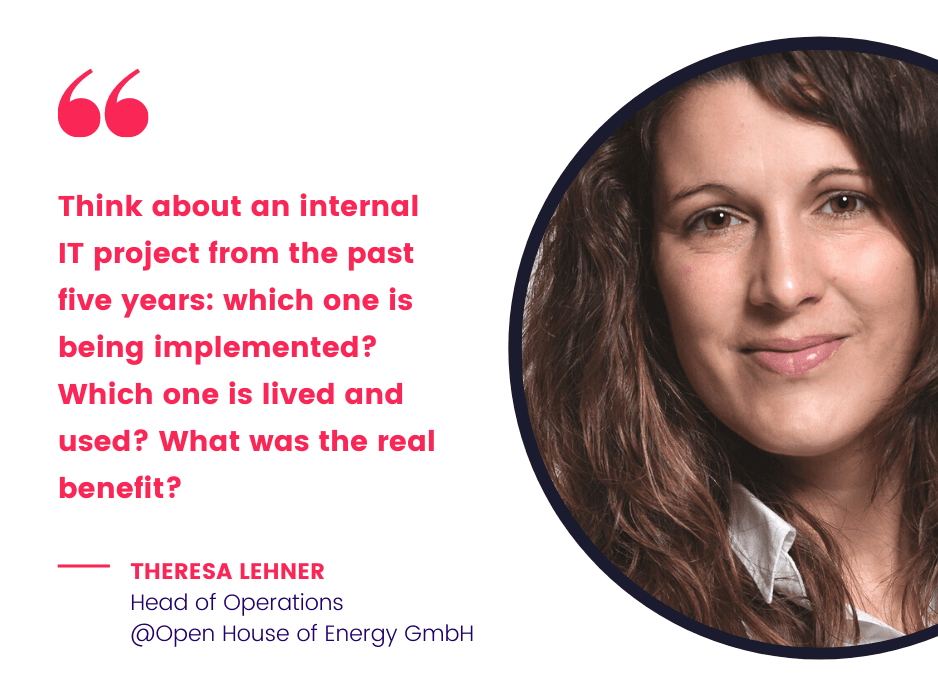

Such an iterative project makes it possible to introduce the team to the new processes and solutions and to ensure their successful implementation in everyday life. Accordingly, the effort for training and retraining is significantly lower than in comparable projects. OHoE sees this potential as a fundamental gain:

Image Credit: Wemakefuture

The key lesson in OHoE’s approach to automation is to think of simple, flexible digital products for scalable, long-term solutions. And that’s exactly what Make allows for.

Ready to make the automation revolution happen?